Mold factor

The design quality of glass mould will directly determine the quality of glass wine bottle. A successful mould will minimize the production error of wine glass bottles. An unsuccessful wine glass bottle mold can not only meet the needs of customers, but also cause a waste of resources and costs.

Enterprise Technology Factors

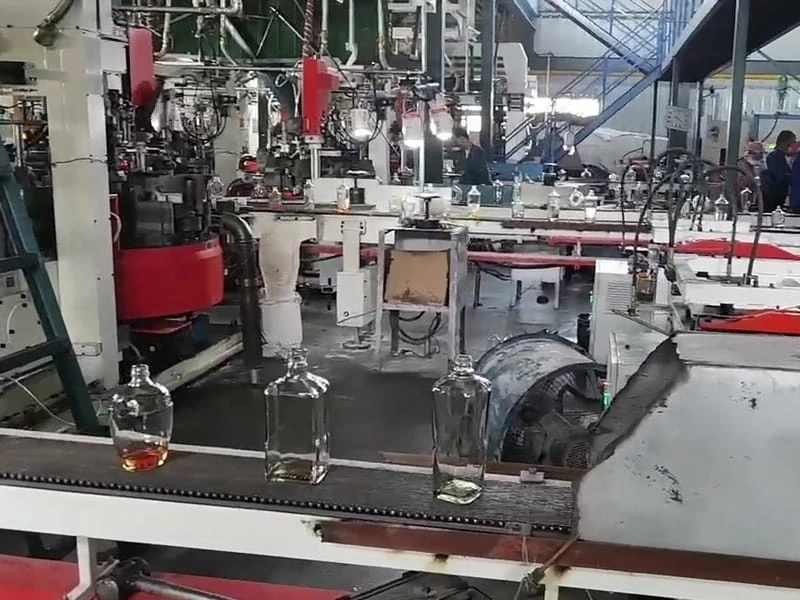

The technical strength of a glass bottle manufacturer (VIT) is the hard strength of whether the glass bottle production is successful or not. When choosing manufacturers, consumers should try to choose manufacturers with large production scale, advanced production technology, avant-garde corporate culture and business philosophy. Such manufacturers often have good reputation and good reputation, and the glass bottle products produced are closer to the needs of customers.

Artificial Technology

The operation technology of the staff of an enterprise will directly affect the quality of products. A successful glass bottle production company has a team of skilled workers.

Annealing Operation

The annealing operation after molding will directly affect the quality of glass bottles. Glass is subjected to intense temperature and shape changes in the molding process, which leave thermal stress in glass products. The thermal stress will greatly reduce the strength and stability of glass products. Therefore, glass products must be insulated or cooled slowly within a certain temperature range after forming, so as to reduce the thermal stress value (commonly known as cold explosion phenomenon).

During the storage of glass bottles, choose the indoor environment to avoid excessive weathering in the natural environment. There should be a certain gap between wine bottles for ventilation, and avoid damage to wine bottles caused by too much humidity.

The glass bottle shall not directly contact the ground to avoid scratches on the product surface caused by impurities. Try to ensure that the ground of the storage area is flat and avoid the danger of falling due to the instability of the glass bottle.