This article offers a comprehensive overview of the glass bottle manufacturing process, covering everything from the raw materials used to the final packaging of products like beer bottles and beverage bottles. Valiant Glass, a leading manufacturer in the glass industry, is dedicated to creating high-quality, sustainable glass packaging solutions.

1. Glass Bottle Manufacturer Raw Materials

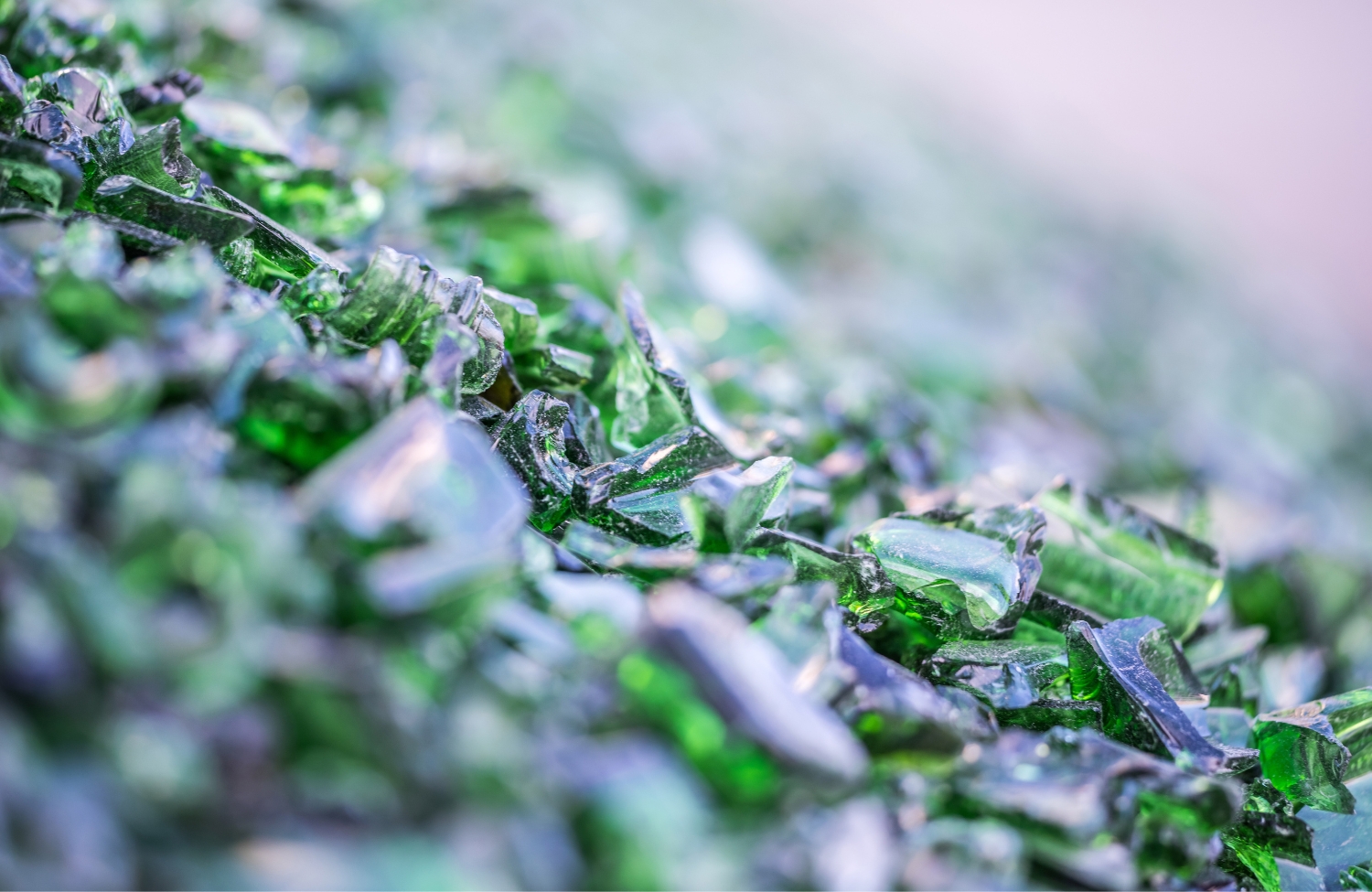

The primary materials used to produce glass bottles include sand, soda ash, and limestone. An essential component of this mixture is cullet, which consists of recycled glass. For every ton of glass recycled, approximately 1,300 pounds of sand, 410 pounds of soda ash, and 380 pounds of limestone can be preserved. This recycling process not only reduces manufacturing costs but also saves energy, allowing customers to enjoy economical prices on our products at Valiant Glass.

2. Melting Glass Bottle Raw Materials in a Furnace

The raw materials and cullet are continuously melted at high temperatures of around 1,650°C in a furnace that operates 24 hours a day. The mixture transforms into molten glass in about 24 hours. From the forehearth, the glass flow is cut into pieces according to weight, with precise temperature control ensuring optimal quality for our glass bottles.

3. Glass Bottle/Jar Forming

There are two main forming methods: Press Blow and Blow Blow, both executed in IS machines.

- Press Blow: In this method, droplets of molten glass are pressed into a blank mold using a metal plunger, forming a parison. This parison is then transferred to a final mold where it is blown to the desired shape. This technique is commonly used for wide-mouth glass bottles but can also produce narrow-necked bottles.

- Blow Blow: Here, droplets are compressed into a blank mold, and compressed air is used to expand the parison into the final mold. This method allows for the creation of glass bottles with various neck thicknesses.

4. Annealing During Glass Bottle Manufacturing

After forming, the glass containers are typically coated while still hot to enhance scratch resistance. This hot-end surface treatment is followed by the annealing process, where the bottles are gradually cooled in an annealing furnace. This step is crucial as it relieves internal stress, ensuring the durability of the glass container.

5. Glass Bottle Quality Inspection

Before inspection, bottles undergo a cold-end surface treatment to cool them to about 100°C, reducing the risk of scratches. For quality assurance, we employ advanced technologies such as LED beam detection and integrated inspection machines. These systems check for faults that are not visible to the naked eye, including sealing surface integrity and dimensional accuracy. Any defective bottles are automatically rejected and re-melted for reuse, ensuring consistent quality in our production.

6. Glass Bottle Packaging

The packaging of glass bottles is tailored to customer requirements. Common methods include:

- Standard Pallet Packaging (Bulk Pack)

- Carton Pallet Packaging (Case Pack)

After completing the manufacturing process, glass bottles are stored according to the required shape and size, ready to be shipped to filling plants.

At Valiant Glass, we pride ourselves on being a comprehensive provider of glass packaging solutions. With our commitment to sustainability and innovation, we serve markets for spirits bottles, including whiskey bottles, vodka bottles, rum bottles, gin bottles, and more.

For inquiries about our custom glass bottle solutions, don’t hesitate to contact us. Explore our extensive range of products, including brandy bottles, white wine bottles, champagne bottles, and red wine bottles.

By focusing on quality and sustainability, Valiant Glass is committed to providing exceptional products and services that help build iconic brands worldwide. For more information, visit our website at Valiant Glass.

If you’re looking for more knowledge of glass bottles, check out the following articles:

– Top 4 Drinking Glass Manufacturers in the U.S

– Top 10 Glass Bottle Manufacturing Companies in India(Latest Updates)

– Top 10 Glass Bottle Manufacturers In The USA

– Why Choose Apple Juice in Small Glass Bottles? A Flavorful Experience

Consult Your Valiant Glass Bottles & Packaging Experts

We help you avoid the pitfalls to deliver the quality and value your glass bottle and jar need, on-time and on-budget.