Mainly include selecting high-quality raw materials, reasonable packaging, handling with care, and correct storage methods.

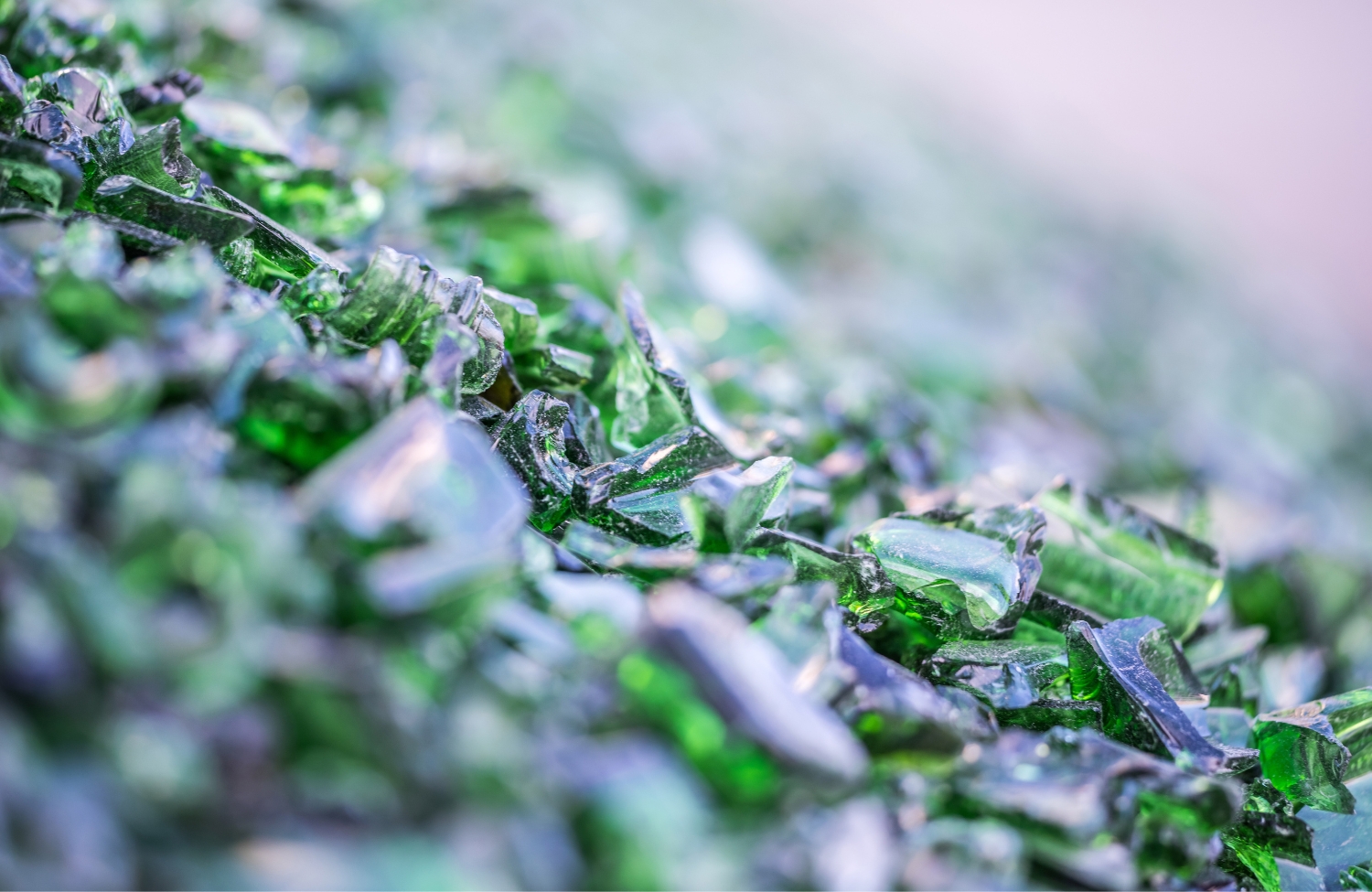

Select high-quality raw materials: ensure the quality of glass bottles and avoid using inferior raw materials. Although the procurement cost has increased, in the long run, the production cost is much lower than that of glass bottles produced with inferior raw materials.

Reasonable packaging:

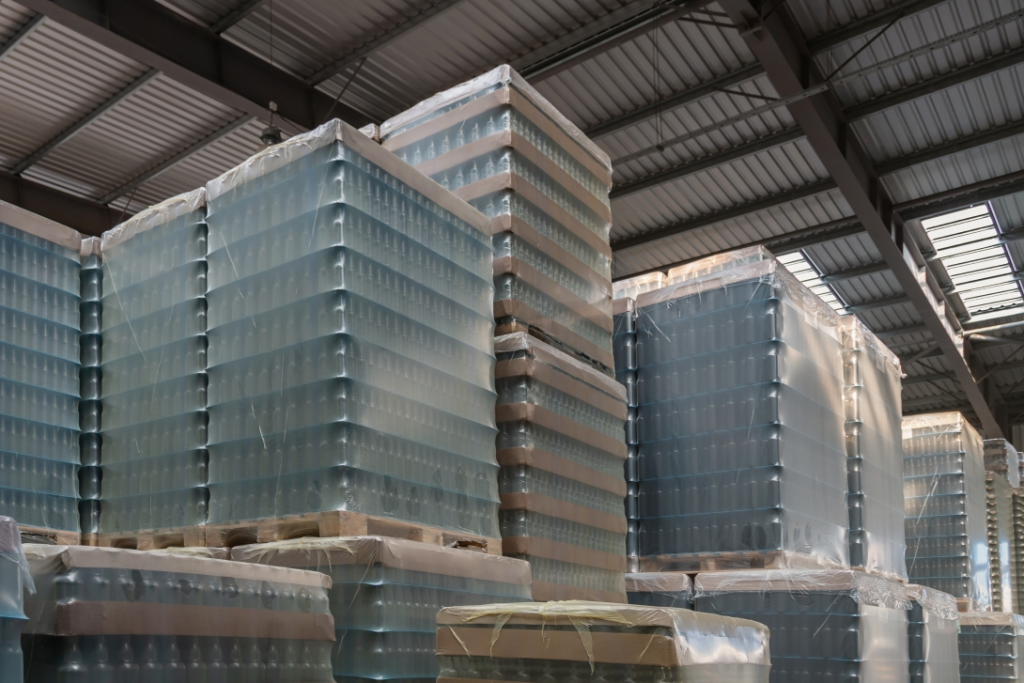

Use thick cartons or wooden boxes for reinforcement, use old newspapers or foam for packaging and barrier on the outside, and separate some harder and more stable boards between layers.

After loading, be sure to tie them tightly to prevent the bottles from shaking or colliding during transportation, causing damage or even breaking.

Cover and protect the products to reduce the damage to the appearance of the bottles caused by the sun and rain, and the excessive pressure on the bottles caused by the large temperature difference, and the cracks caused by thermal expansion and contraction affect the quality and sales.

Handle with care: During transportation, you should handle it with care and make full use of packaging materials to reduce the breakage rate of glass wine bottles during transportation.

Correct storage method: After the wine bottles arrive, they should be stored in a flat area to avoid the danger of falling due to imbalance.

In addition, the risk of glass bottles being damaged during transportation can be further reduced by choosing sturdy packaging boxes, filling and protecting the bottles, sealing the bottle mouths, and choosing professional express delivery companies