- Blowing process

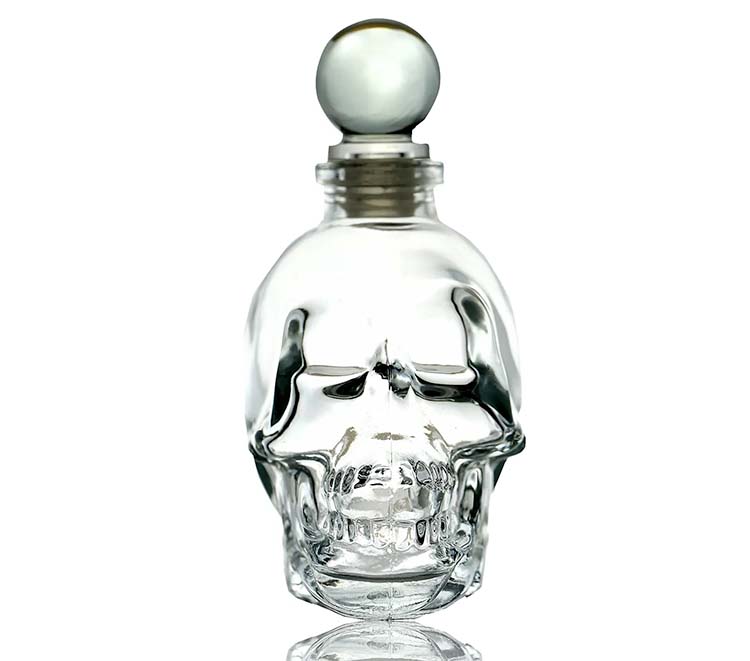

The blowing process of glass bottles is currently the most common production method. The main process of this process is to heat the glass blank to soften it, and then use a blow pipe to blow gas into the blank to form the bottle body. Finally, after cooling, annealing and other process steps, the finished glass bottle is obtained.

The advantage of the blowing process is that it can produce glass bottles with different shapes and unique designs. At the same time, the process is low-cost and suitable for mass production, so it is widely used in industrial production. - Tempering process

Tempering is a process of heat treatment of glass, and it is also one of the common glass bottle manufacturing processes. In the tempering process, the glass is heated to high temperatures and then rapidly cooled, causing compressive stress to occur on its surface, thus improving its strength and impact resistance.

The advantage of the tempering process is that it can make the glass bottle have higher strength and durability, better resistance to thermal shock and distortion, and can prevent it from cracking or breaking, ensuring the safety of the glass bottle. - Coating process

The coating process is a process of coating a protective film on the surface of glass bottles. In the coating process, different methods such as spraying and screen printing are usually used to apply the protective film. This process is suitable for personalized processing such as patterns and patterns on the surface of glass bottles. At the same time, by coating a layer of film on the surface, the wear resistance and UV protection of the glass bottle can also be enhanced.

The advantage of the coating process is that it can personalize the glass bottle and make it waterproof, sun-proof, and anti-wear. At the same time, the coating process can also reduce defects on the surface of glass bottles and improve their aesthetics and quality.

To sum up, blowing process, tempering process and coating process are several processes commonly used to make glass bottles. Each process has its own characteristics, advantages and disadvantages. We can choose the appropriate glass bottle process according to our own needs and usage scenarios, thereby improving its quality, safety and practicality.