In the midst of a competitive market the ability to make your wine stand in a crowd is vital. The label can tell a story while the inside of the bottle provides the pleasure and the bottle? It’s usually the first contact with the customer. Bottle shapes that are standard are common, however the custom-designed wine bottles provide a unique method to draw interest, establish brand recognition as well as create a distinct image.

The market of customized glass bottle designs isn’t a one to take without a lot of thought. There are specific concerns to be considered regarding the feasibility of design, costs as well as production timeframes and the alignment of your brand. Prior to launching into designing a custom bottle, this article will help you understand all the important factors to think about. Being experts in glass container production and design, Vaillant Verre will ensure that you are equipped with the necessary information to choose the right bottle to promote your business.

Why Even Consider Custom Shape Wine Bottles? The Allure of Uniqueness

The attraction of a customized bottle is evident. It stands out from the sea of similarity that is available on shelves. There are many reasons why brands take this avenue:

- unmatched brand identity Unique silhouettes can be instantly recognized and associated with your business. It’s a concrete image of the wine’s character whether it’s contemporary, classic, fun or extravagant. The visual difference helps to build an image that is remembered for a long time after the bottle is empty.

- Enhanced Shelf Presence Shapes that are custom-designed naturally catch the eyes. In an environment of competition being noticed visually could greatly influence consumer choices. An item that is intriguing will entice shoppers to open the bottle up and find out more.

- Storytelling Potential The form itself is able to create a narrative or invoke the theme of the vineyard’s history, place of origin or even the wines’ characteristics. This adds another dimension to the story of your brand.

- Premium Perception A lot of times, distinctive packaging can be associated with better quality or exclusiveness. The custom-designed bottle could increase the perception of value for your wine and could help to support the idea of a premium price.

Key Considerations Before Committing to Custom Glass Shapes

Although the advantages are appealing designing custom wine bottles is a process that requires the right planning and investments. These are the most important aspects to be evaluating prior to you begin designing your bottle:

Design Feasibility & Practicality in Glass

It is not always possible to translate an imaginative design effectively into a glass bottle. Glass bottle manufacturing is a process that has certain specifications:

- Structural Integrity The bottle should be sturdy enough to stand up to the pressure (especially in the case of sparkling wines such as Champagne Bottles Bouteilles de champagne) as well as handling as well as transportation. Thin sections or complex angles may result in weak points.

- Stability It is essential that the base be sturdy to avoid the tables and shelves from tipping over.

- Pouring performance: The neck and opening designs must permit easy flowing, non-drip pouring.

- Labeling and Decoration: Take into consideration how labels stick to irregular or curving surfaces. Make sure there is enough surface, either flat or slightly curved for the primary label, the back labels and required regulations. Certain shapes could require the use of specialized equipment for labeling.

- Compatibility of Filling Lines Does the customized form work with conventional bottling equipment? Any significant deviations could require expensive changes to your filling, corking, or the packing process.

Minimum Order Quantities (MOQs)

The creation of a custom-made mold is an expensive upfront expense for the company that produces. For this to be economically feasible, custom shape wine bottles typically require greater minimum order amounts (MOQs) in comparison to bottle sizes. Expect commitments in the range of tens to thousands up to hundreds of thousands of bottles in a production run. Make sure your projections for sales can handle these numbers.

Costs Involved: More Than Just the Glass

The cost per bottle of personalized shapes will be more than normal bottles because of a variety of aspects:

- Mold Development It is a once-in-a-lifetime cost, recurring engineering (NRE) cost. However, it may be substantial comprising engineering, design and even the production of a mold set.

- Production Costs Custom designs may be more slowly on production lines, or require more specific handling. This could result in slightly higher price per unit of manufacturing.

- Possible Downstream Costs Like I said, take into account any adjustments that may be required to marking, filling or packaging equipment.

Timeline: Patience is Key

The creation of a customized bottle won’t be the case in an instant. Be prepared for a timeframe that comprises:

- Concept and Concept Phase Months or weeks based on the the complexity of the project and its modifications.

- Technical Drawings and 3D Modelling: Refining the design to improve manufacturing efficiency.

- Mold Development: Typically takes several weeks or even a couple of months.

- Sampling and Testing The production of initial samples to allow to be tested and approved (e.g. capacity and pressure tests or line trial).

- Full-Production Run Time frames for lead times differ based on the capacity of the manufacturer and schedule. Make sure to plan a complete time frame of development that is several months starting from the initial idea to getting the bottles finished and in stock for filling.

Brand Alignment: Does it Truly Fit?

Do you honestly think that an individual shape truly help your brand’s identity and messaging and brand, or is it simply something that’s a unique idea? It must be genuine and significant, coordinating the style of your wine as well as its target market as well as your overall marketing plan. An unbalanced design can make consumers feel confused instead of attracting consumers. Take a look at if a distinctive design in a bottle can be able to achieve the same results with a smaller cost.

The Custom Bottle Creation Process: A Brief Overview

A better understanding of the standard workflow could assist in managing expectations:

- Concept and Ideation Participation in discussions on branding goals, desirable aesthetics and constraints in the field of technology.

- Designs and technical drawings: Transforming ideas in elaborate 2D and 3D models that specify capacities, dimensions as well as glass weight and the finish.

- Mold Engineering & Manufacturing: Making the exact molds made of metal for the production of hot glass.

- first article samples A small quantity of samples for evaluation, testing, and finally acceptance.

- Mass Production When samples are accepted, schedule and run the entire production schedule.

- Contrôle De La Qualité Continuous checks throughout the entire process to ensure uniformity and conformity to the specifications.

- Decoration (Optional): Applying labels, screen printing coatings, etching or any other elements of decoration to the final bottles.

Standard vs. Custom Shape Wine Bottles: A Quick Comparison

In order to assist you in weighing the alternatives, here’s a chart which summarizes the most important differences

| Fonctionnalité | Basic Containers (e.g. the typical bouteilles de vin rouge, Blanc Bouteilles De Vin) | Custom Shape Wine Bottles |

|---|---|---|

| Uniqueness | The price is low; the shapes are widely available. | High, unique for your business |

| Brand Impact | Depends heavily on the label/decoration | High Shape in itself creates the brand’s credibility |

| Upfront Cost | There is none (for the design it self) | Significant (Mold Development) |

| Unit Cost | Generally Lower | Generally Higher |

| MOQ | Low to Moderate | High to Very High |

| Lead Time | Short (Often readily available in inventory) | Long (Months for development + production) |

| Design Risk | Low; Proven shapes | Moderate. Requires careful engineering. |

| Flexibilité | Available shapes | High (within the manufacturing limit) |

Finding the Right Manufacturing Partner

The right glass supplier is essential to ensure success when making customized bottles. Choose a supplier who:

- Proven Expertise Extensive experience working in the glass industry, especially using custom models.

- Design & Engineering Support: Capabilities to help transform your ideas into real-world product that can be manufactured.

- Quality Commitment Effective quality control methods starting from raw materials and ending with finished items.

- Collaboration Approach: Willingness to work closely with you through the process of development.

- Complete Service: Ideally, a partnership such as Vaillant Verre that integrates design, production and decoration and provides a seamless, all-in-one solution.

Beyond Wine: Custom Shapes for Spirits and More

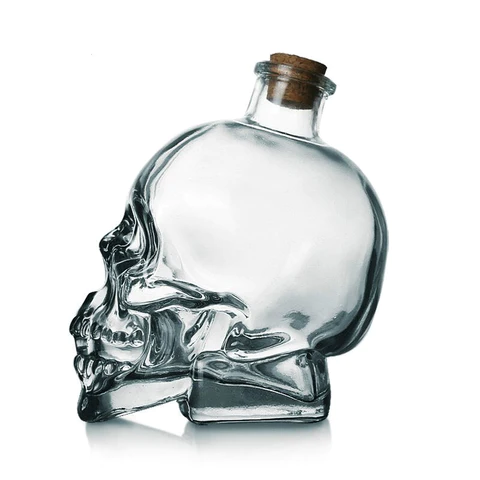

While this article is focused specifically on wines, tenets of custom-designed glass designs apply equally to other types of beverages. The trend for unique shapes is increasing for craft spirit Bottles that include distinct Whiskey Bottles Elegant Vodka Bottles and distinctive Rum Bottles and botanically inspired Gin Bottles as well as sophisticated Brandy Bottles. These same factors of the feasibility of cost, timeframe and branding are applicable.

In addition, understanding the qualities and sustainable qualities of glass are crucial. Glass is not just gorgeous but it is also healthy, pure and completely recyclable and recyclable, which makes it an ideal option for environmentally sustainable packaging. (Learn more about the sustainability of glass through resources such as The Glass Packaging Institute).

Conclusion: Is a Custom Shape Right for Your Wine?

Custom-designed wine bottles provide an opportunity to distinguish your business and make an unforgettable impression. It’s also a crucial option that needs careful evaluation of creative potentials in relation to the real-world realities of manufacturing, cost as well as volume commitments and deadlines.

Before making the jump take a look at the advantages and these important factors. Learn about the process, plan your plan your budget, and select an industrial partner who has an understanding of how for bringing your ideas to fruition in a timely and elegant manner.

Are you ready to investigate the possibilities of customized glass packaging? The team at Vaillant Verre have the expertise as well as cutting-edge technology that can help to create inspirational, creative packaging. Get in touch with us now to discuss the possibilities for your packaging.

Si vous êtes à la recherche pour plus de connaissances sur les bouteilles en verre, consultez les articles suivants:

– Top 4 de Boire des Fabricants de Verre dans le U. S

– Top 10 des Bouteille en Verre Entreprises de Fabrication en Inde(Dernières Mises à jour)

– Top 10 des Bouteille en Verre Fabricants Dans Les états-unis

– Pourquoi Choisir de Jus de Pomme dans de Petites Bouteilles en Verre? Une Savoureuse Expérience

Consulter Votre Vaillant Bouteilles En Verre Et Emballage Des Experts

Nous vous aidons à éviter les pièges à offrir la qualité et la valeur de votre bouteille en verre et un pot de besoin, sur les délais et le budget.