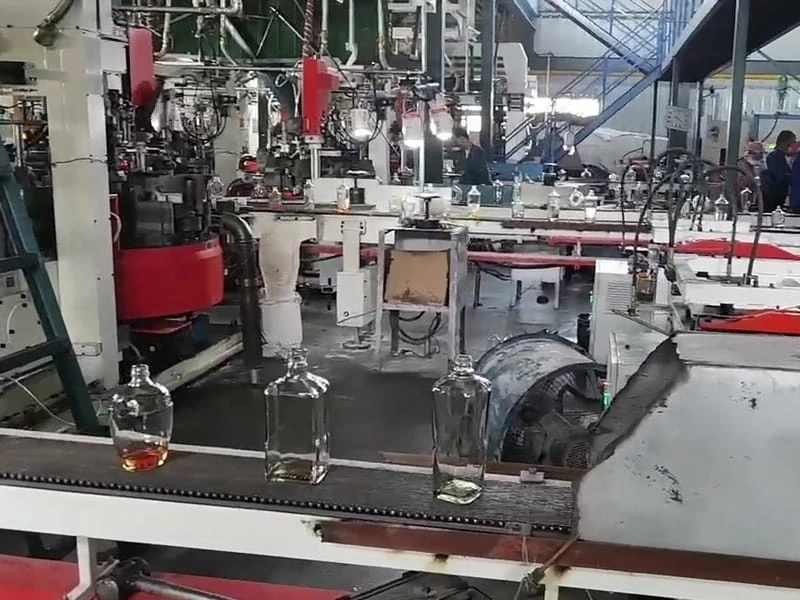

Glass bottles are prone to irregular conditions in the processing process, such as distorted bottle frame, lack of cork or inclined bottle bottom. In that way, the manufactured 750ml bottle can not ensure excellent tightness, and there will be certain risk factors. So how to deal with such conditions in the processing process and how not to produce defective products? Let valiant glass bottle manufacturers explain to you below.

There are some irregularities in the whole manufacturing process of 750ml bottles. Due to the unscientific stamping die, there are certain shortcomings, which distorts the appearance of 750ml glass bottles. In other words, when the raw materials are added, the temperature and time are not grasped well, which leads to the deformation of Baijiu bottles. In other words, the glass bottles are removed without complete condensation during the whole quenching process, resulting in deformation under the external effect.

Strictly ensure that the abrasives are neat, so as to avoid the deformation of the glass bottle in many aspects. In the processing process, it is necessary to strictly control the order of temperature and time, strictly implement the regulations to prevent the deformation caused by great charm, and finally do a good job in the quenching process of the glass bottle. It is the final process of glass bottle manufacturing, which ensures the uniformity and goodness of the glass bottle.