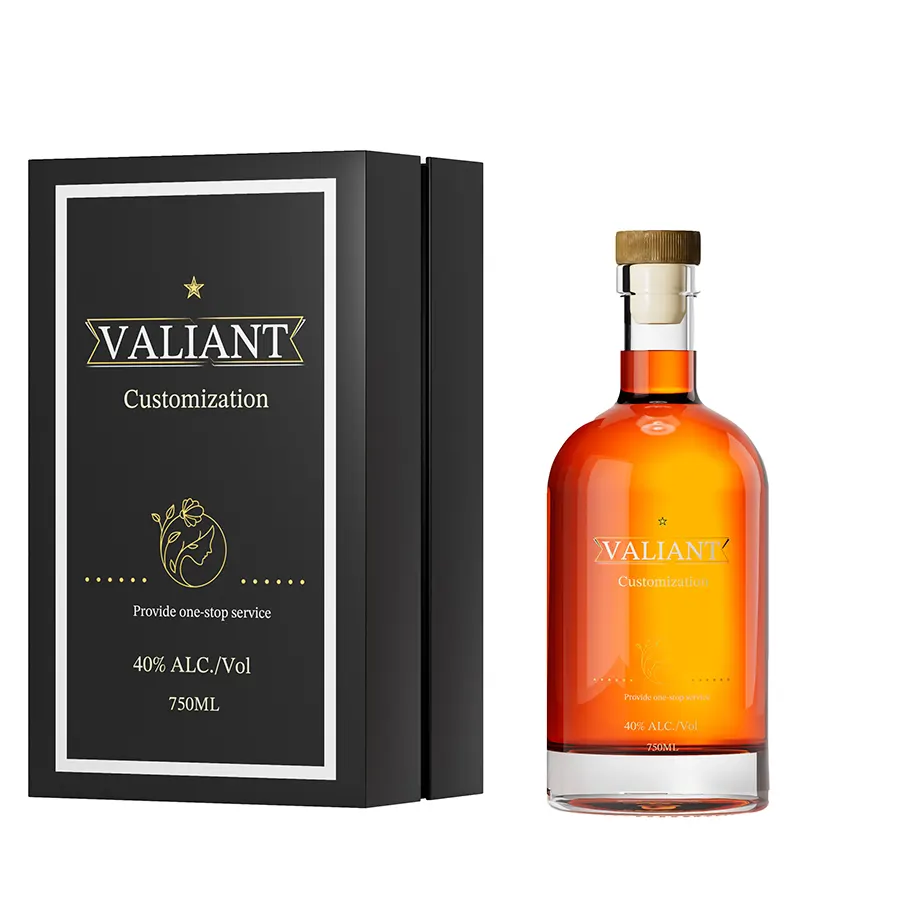

Customize your bottle, Distinguish your brand

Idea communication

for shape,capacity,closure and decoration

We offer a wide range of innovative packaging solutions to keep your brand fresh. We are also happy to help you realize any ideas you may have.

Confirmation by technical drawing

Make 3D model according to the design or customers’ glass container samples.

Sample mould and sample bottle production

Manufacture, test and evaluate customers’ glass container samples.

Sample bottle confirmation

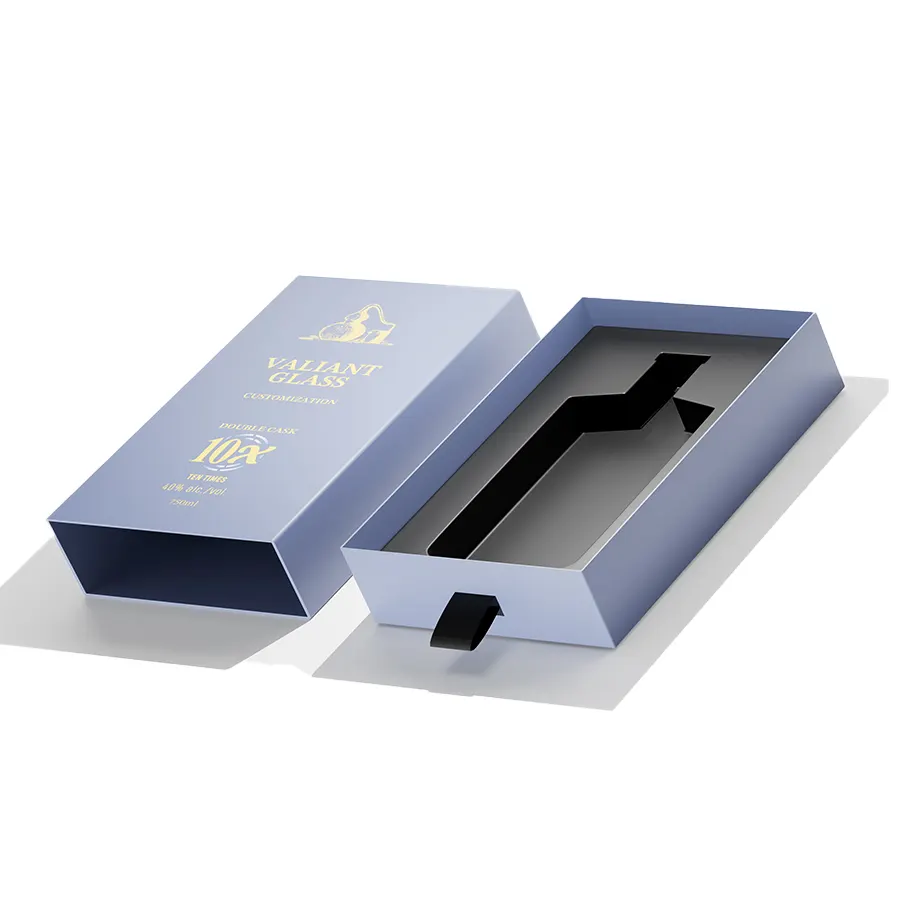

Ship samples to our customers. After they confirm that there is no problem with the samples, mass production begin.

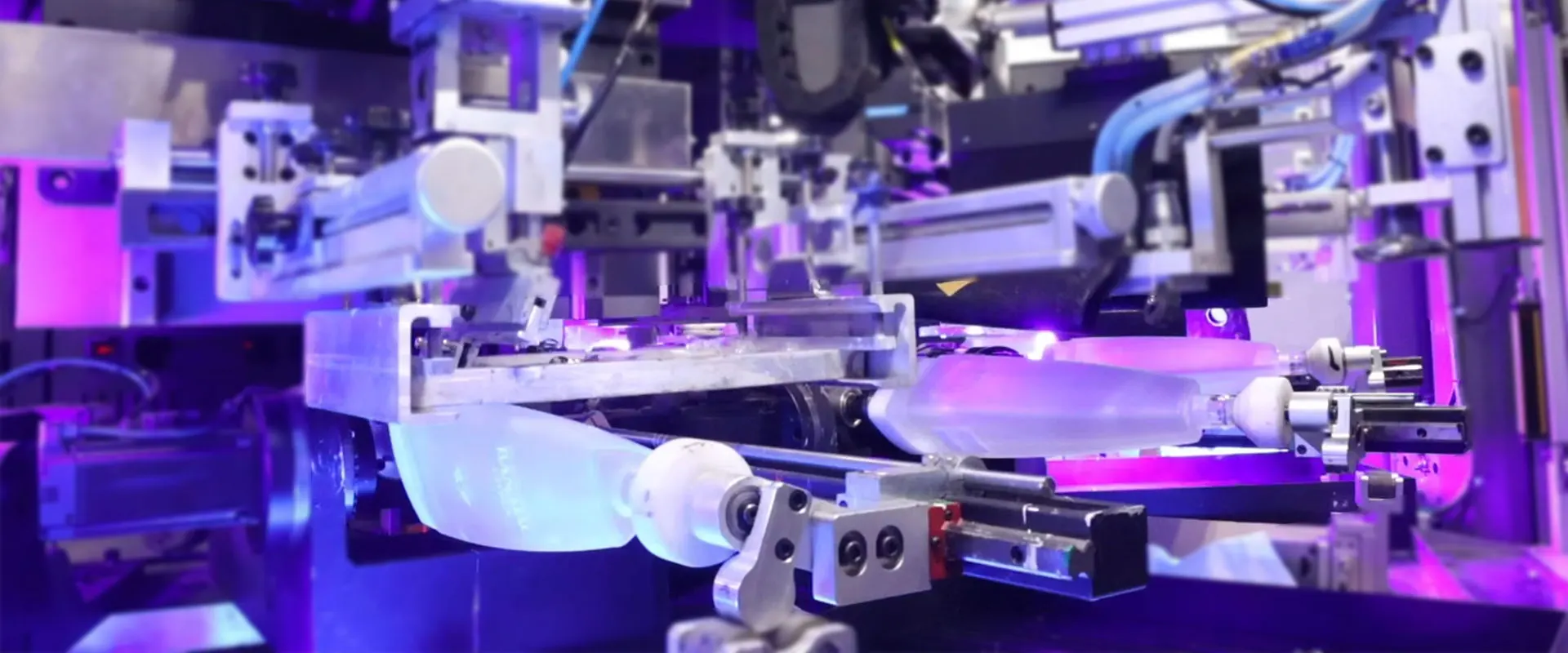

Mass production mould and bottle

production

Our mass production allows your company to move through production phases easily and quickly.

Quality Inspection, Packaging, Delivery

After-sales tracking service

We provide high-quality packing to ensure the safety of your products during transportation.

Process Description

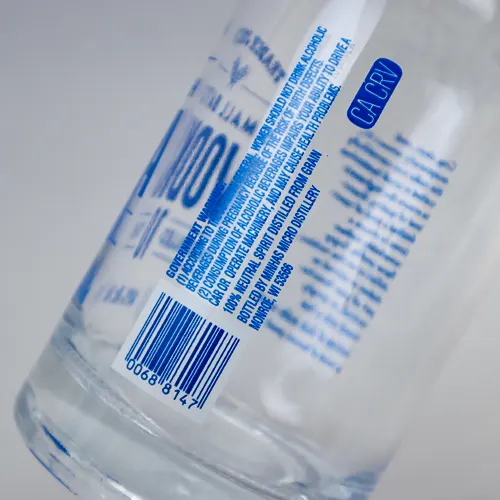

Silk Screen Printing

Many colors available, cost effective, easy to operate,long lasting effect. Including enamel screen printing, precious metals screen printing, organic screen printing, etc. Can achieve embossing effect easily with the printed pattern.

Hot Stamping

Hot stamping or foil printing is one of the most cost-effective decoration techniques for branding or customizing a packaging component. Hot stamping is a printing method which consists in transferring a metal foil on the surface of the object thanks to a cliché and the action of heat. The stamp thus obtained can be golden, silver and other colors available to the customer.

but for glass bottle, you can not stamping on glass bottle directly, you need printing stamping base ink by screen printing at first, then stamping onto the ink will be get the stamping result.

Decal

Good for irregularly-shaped bottle decoration, uneven and limited surface area. Lots of colors available, intricate details presentation. One of the best methods to present your logo and design pattern onto the glass bottle. Great combination effect with acid etching, color coating and metallization etc.

Frosting

Through an acid etching process, the outer layers of the glass bottles is removed, giving the bottle an opaque, frosted appearance. The texture can be more or less rough, depending on the grade used. Sandblasting reserves can be created, enabling patterns and insets to appear in specific areas of the bottle.

Coating

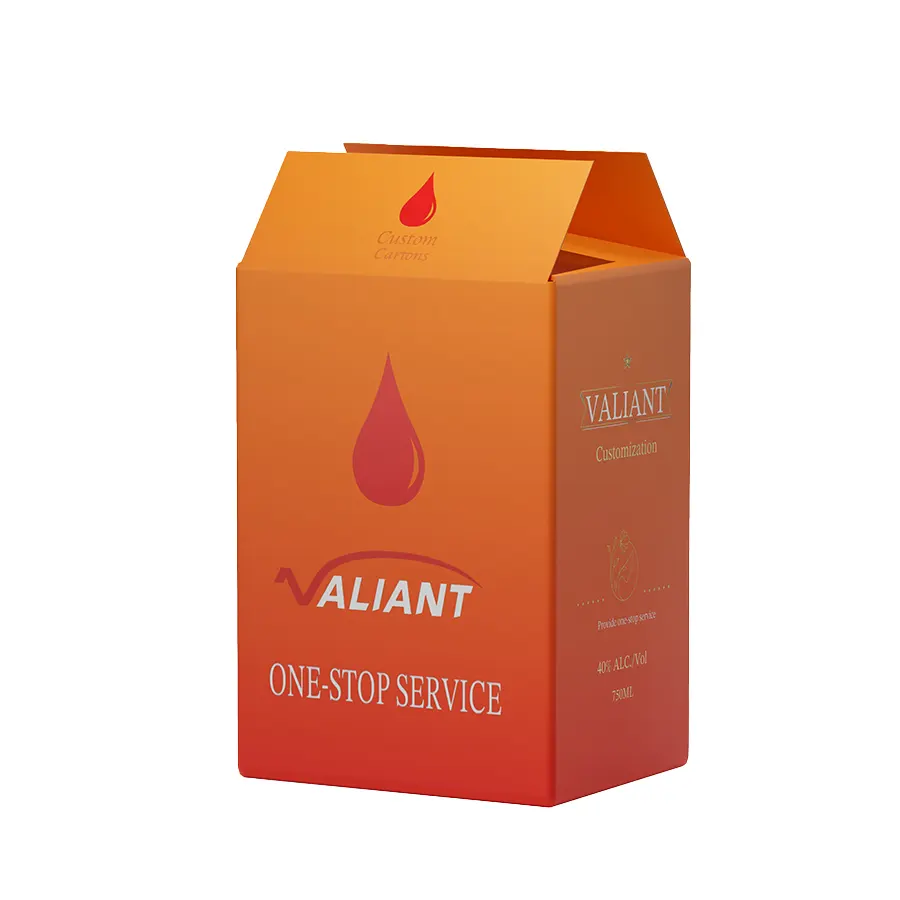

Many colors available, eco-paint, bright, matte, etc. Fully or partly color coated and gradient color available for client’s individual design.

Carving

Electroplates

Closures Caps and Corks

Cartons

WHY VITGLASSBOTTLE.COM?