Introduction:

Glass bottles have been an integral part of civilization for centuries. They are not only functional containers but also aesthetically pleasing objects. Have you ever wondered how these versatile vessels are made? In this article, we will explore the fascinating process of crafting glass bottles, from the raw materials to the finished product.

Gathering Raw Materials:

The first step in making a glass bottle is collecting the necessary raw materials. The primary ingredient is silica, which is obtained from sand. Other additives, such as soda ash, limestone, and cullet (recycled glass), are mixed with the silica to enhance the glass’s properties and reduce its melting temperature.

Melting the Glass:

Once the raw materials are gathered, they are combined in precise proportions and transferred to a furnace. The furnace operates at extremely high temperatures, typically around 1500°C (2732°F), to the mixture into a molten glass.

3.aping the Bottle:

After the glass has melted, it is ready to be shaped into a bottle. There are two common methods used for shaping glass bottles: the blow-and-blow method and the press-and-blow method.

Blow-and-Blow Method:

In this traditional method, a glassblower gathers a small amount of molten glass on the end of a blowpipe. The glassblower then blows air into the pipe, creating a bubble within the molten glass. The glassblower shapes the bubble by rotating and blowing into the pipe, gradually forming the bottle’s body. After shaping the body, the glassblower uses various tools to create the neck and mouth of the bottle.

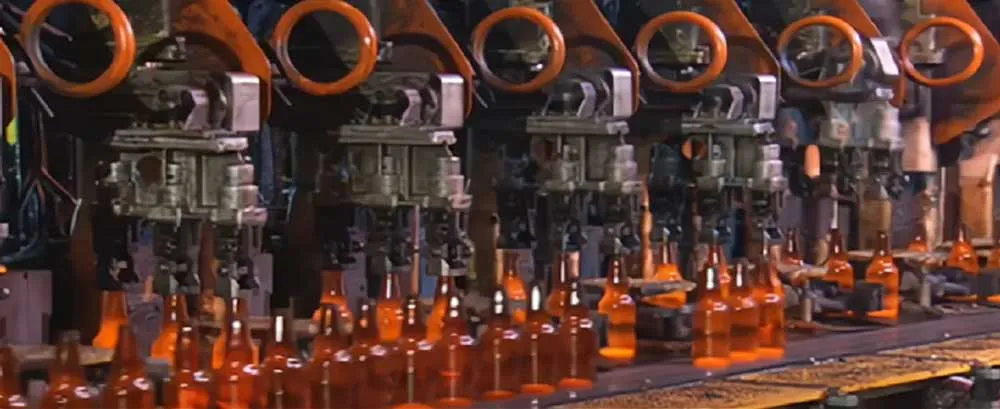

Press-and-Blow Method:

In this method, a machine called an IS machine (Individual Section) is used. The IS machine consists of several sections, each responsible for a specific part of the bottle-making process. The molten glass is fed into a mold, and a plunger presses the glass into the desired shape. The mold is then opened, and the newly formed bottle is removed.

Annealing:

Once the bottle has been shaped, it undergoes a process called annealing. Annealing is the controlled cooling of the glass to relieve internal stresses and increase its strength. The bottle is placed in a temperature-controlled chamber known as a lehr, where it gradually cools over several hours. This process ensures that the glass is strong and durable, reducing the risk of breakage.